On Monday I'll put down what I hope/expect to happen during this very critical week. Then on Sunday night I'll compare it to what actually did happen. This could be interesting in several ways...

---------------------------------------------------------------------

Monday, 29 January. 20 work sessions in, 17 until our practice event ( 20 to stop work day ).

We are now at the half way point in build season. All critical systems have at least passed "proof of concept" stage and most have been improved upon. But it is still a bunch of unconnected parts.

My hopes for the week.

Final frame, sufficient to support the mast and to mount everything in place.

Practical mounting platform for the Bear Claw, built and installed.

Uptake spool for elevator winch created, tested, works.

At least a preliminary plan for fitting everything inside the robot. We need Winch 1 and 2, electronics, air compressor, at least two air tanks, battery.

Give software a chance to drive a few days with a more or less competition robot to see if it is stable. I understand they are going to adjust the robot's ability to accelerate/decelerate automatically depending on how high the elevator is up off the floor. That's pretty impressive programming.

Finish robot cart and build a target for our "high goal".

Bumpers constructed with easy install system.

----------------------------------------------------

The insider's view at mid week: 23 sessions done/14 to practice event

End of day Sunday. 10 (maybe 11) sessions until our practice event. 15 to bag and tag. My photos are a mix of Saturday and Sunday shots, we made enough progress that some systems are being taken down for rebuild/improvement.

My list:

Frame is done. Just need to get that back ordered winch and drop it on somehow.

Bear Claw works so well that we are reluctant to upgrade it, but there is one part made of polycarbonate that would be better in aluminum. The original part goes in the back up spares.

Uptake spool works great. Need to shore up its attachment point as a slipped cable means a failed match. Software will program a smooth start to the winch to avoid sudden jerky motion.

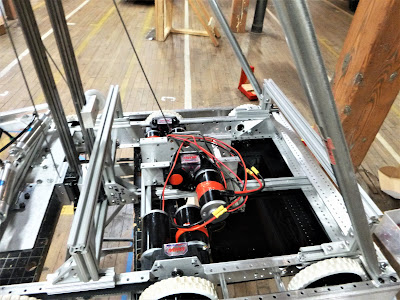

Everything fits, but obviously we have a big bowl of wiring spaghetti. A team is working on compact, easy to work around control boards.

Cart done and looks great. Bumpers are an ongoing project. We have had an ever changing work crew and some warped plywood to contend with.

The only failure for the week was making a "high goal" target. The donated materials we were working with had some odd connectors that used up time and lead nowhere. But if you know you can hoist that box to the required height, is it crucial to prove it...I mean, we have a tape measure!

We have a 120 pound weight limit. We had been driving around with an extra five pounds of "mast" on top, partly to see if it would handle at all reasonably being top heavy. It was actually not too bad. So time for some robot surgery, cutting it down to the required 55 inch starting configuration. Surgeons need to be careful and confident. The sharp eyed might notice the sleeve of my coat in this picture. We always cover electronics carefully when sparks and shavings are flying. My coat was just handy. Weight looks like it will come in around 110.

After a superb Saturday session Sunday was a bit of a let down. Oh, things got done but only small, necessary things. The Claw was rebuilt in heavier metal. The aluminum mounting plate was started. The cable attachment to the winch was improved. A cable management system was tried and failed. We did give the robot back to the software folks and for unclear reasons something that worked the day before now chose not to. Mechanical issues are so much more straightforward.

But we are on track. In fact a rather clever new mechanism is being worked on. Since our elevator is powered drive up and passive drift down it really should have a means of locking in place when we want to stay at a certain height. Such a device is now under development....

So a good week. Ahead lies the dreaded Week Five when everyone is getting tired of robots. Progress is likely to slow.

No comments:

Post a Comment