Going from wood to metal.

We had our FIRST robot in reasonably complete form by the time of an open house for our hosts Machine Tool Camp. It hopped over obstacles and fired a ball more or less on target. But after a while the pounding it took started to be too much and efficiency declined. You can only ask so much from wood, plastic pipe and duct tape.

So the team tore it down. It was remarkable how fast this process went. Almost two weeks to build it up. 20 minutes to reduce it to parts. An observer noted that it was like watching hyenas going after a carcass!

Time to redo in metal. Fire up the plasma cutter!

As our remade robot started to increasingly resemble a tank we got to wondering just how much of an issue we would have with radio (wifi actually) reception under all that metal. I asked several mavens and got various answers. So I told the software team to try running the controls with the electronics inside a metal pipe. Some useful data was obtained.

I have always liked to have a bit of wood in my robots. Old School I guess. And I think it also buffers vibrations to some extent. I told the kids to paint it whatever color they liked. A nausea inducing yellow? Well, OK. Here several sets of hands are crowding in to ratchet down bolts on the back frame element of the robot.

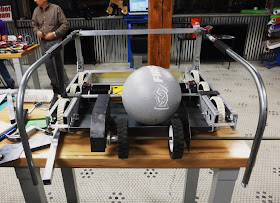

We found that the standard "kit" that rookie teams get from FIRST, while great in other ways, is not so hot regards frame building. It took way too much time to fashion the back part of the frame. After a team discussion we opted to go a different direction for the rest of it. We had already decided on using EMT conduit for the sweep arm. Heck, lets just get a heavier gauge version of it and complete both sides of the frame with one pipe bend each. We obviously have some trimming and support elements to add on the front half of the robot, but you can see the basic shape of things and I personally think it is rather elegant.

Note the ball set in what will be the launching pad for same, also the new and better protected crawler motor mount.

FIRST updates have been weekly but if we stay on track it might be possible to have more worth showing after our long Saturday session.

At the end of the work day we load up our cart and roll our tool cart into what must be the finest storage area any FIRST team on earth can claim.....our own walk in safe! The building we work in used to be a shoe factory and presumably this is where the payroll was kept.

The actual robot is getting too big to easily move in and out, so it rides up to the second floor in a freight elevator. What? You mean all high school robotics teams don't have their own freight elevator?